Published February 22, 2018

Managing a successful manufacturing company isn’t without its stresses and straIns. In fact, your success is bound to create growing pains from time to time.

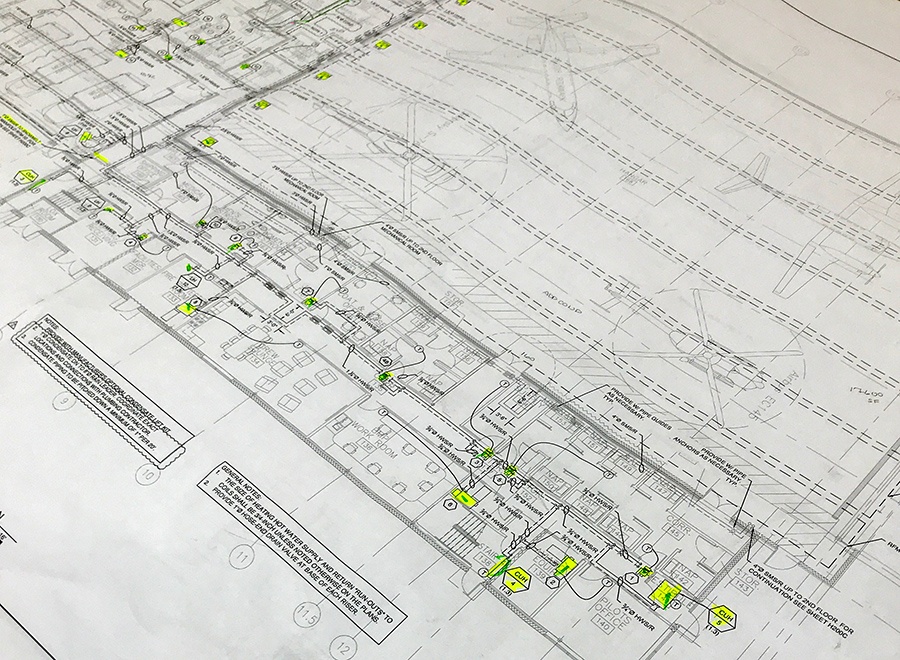

Those pains include everything from needing to expand the square footage of a physical plant to upgrading essential systems like process piping, HVAC, fire protection, and more.

1. Keeping up with demand has become a problem. There’s a demand for your products, but production and delivery times are pushed back due to the lack of adequate space. Alternatively, you may know that there will be increased demand for your products in the near future.

2. Space is tight for both employees and equipment. When there’s barely any free space and work areas feel congested, it can be difficult to operate efficiently. And if lack of space prevents process or customer service improvements, it’s time for serious evaluation.

3. You are adding a product line or new equipment. Naturally, the addition of new manufacturing lines or the acquisition of equipment for your business often demands more room. There comes a time when “squeezing it in” just doesn’t work anymore.

4. Utility costs to operate and maintain your facility are high or expected to rise in the near future. This particularly applies for HVAC, security and fire protection, and other systems. Energy efficiency improvements, process piping upgrades, and fire protection modernization are all areas in which performance improvements can enhance production and reduce costs.

5. Financing costs are currently low, but may be on the rise. It’s a good idea to investigate whether the “savings” of holding off on space or systems improvements will actually cost you more if you wait. It’s also a good idea to research any economic development initiatives in your region that might offer incentives for plant expansion or hiring more workers.

Often, a manufacturing plant isn’t ready for an expansion, but its systems need modernization — an improvement that can boost productivity and cut costs.

Often, a manufacturing plant isn’t ready for an expansion, but its systems need modernization — an improvement that can boost productivity and cut costs.

PSI has experience helping a multitude of companies upgrade without disruption. Process piping, HVAC, and fire protection improvement projects can be phased-in or completed during down-times, keeping production lines humming along uninterrupted.

In fact, new process piping solutions and equipment can benefit your plant even if major construction is not in the cards. Upgraded fire protection systemscan offer increased protection and safety for your most important assets: your employees, your physical plant, and equipment.

In addition to large-scale printing and production plants, PSI has worked with many manufacturing companies including hummus producer Tribe and paint manufacturer Benjamin Moore. These companies have needs that are largely process-related, rather than those due to constraints of physical space. They not only need to pipe water or dry chemicals for fire protection, but also steam, paint, volatile ingredients, and food products. Like circulation systems in human bodies, process systems are the lifeblood of your business and are critical to maintaining its optimum production.

At PSI we work together to create memorable relationships with our clients. Our “No Headache” policy means you can always count on us to be reliable, high-performing, professional, knowledgeable, and highly-efficient problem solvers. Take a look at our “No BS Warranty”.

When you hire the PSI Team, you not only get process piping, fire protection, HVAC, and electrical services, you also benefit by our award-winning safety program, our commitment to community, and a warranty that goes well beyond the industry standard.

Be efficient with your time and trust PSI to be efficient with your piping project. We promise that in the long run, you will be glad you did. Have any questions? Drop us an email at psi@PipingSystemsIns.com or give us a call today at 508.644.2221.