Some might think of heating and cooling only in terms of climate control. Yes, we have seasoned experts who know how to keep you cool in summer and warm in winter. But there are many ways to harness the power of heat and cold to increase your building’s temperature efficiency, boost employee productivity, and save you money simultaneously.

When a boiler goes down in peak season, and there’s no heat, a bad circulator, or a ruptured or frozen line, no one likes waiting for a repair. That’s why PSI offers round the clock emergency repair and installation for our clients. (With our regular maintenance plan, you may not ever need emergency service.) Our expert technicians have seen it all. They understand the urgency behind every service call and know how to assess the project so they bring the right tools and equipment the first time–or know where to get the fastest delivery on parts that are needed. When an HVAC system goes down, other systems are often affected too. We’ve got your back.

Chilled water systems have many uses both for processes and for comfort needs. They’re ideal for medium- to large-sized buildings, providing superb energy efficiency. If your manufacturing processes generate excessive heat, a chilled water system is indispensable in providing the cooling necessary to keep equipment, such as extruders or hydraulics, functioning efficiently.

Waste heat recovery systems maximize energy efficiency by reclaiming excess heat given off by equipment used in the manufacturing process. Equipment that’s exhausting hot air can be brought back to the facility as energy recovery. Rather than emitting a green-house gas, you recycle the energy which lowers your energy cost and helps reduce your carbon footprint.

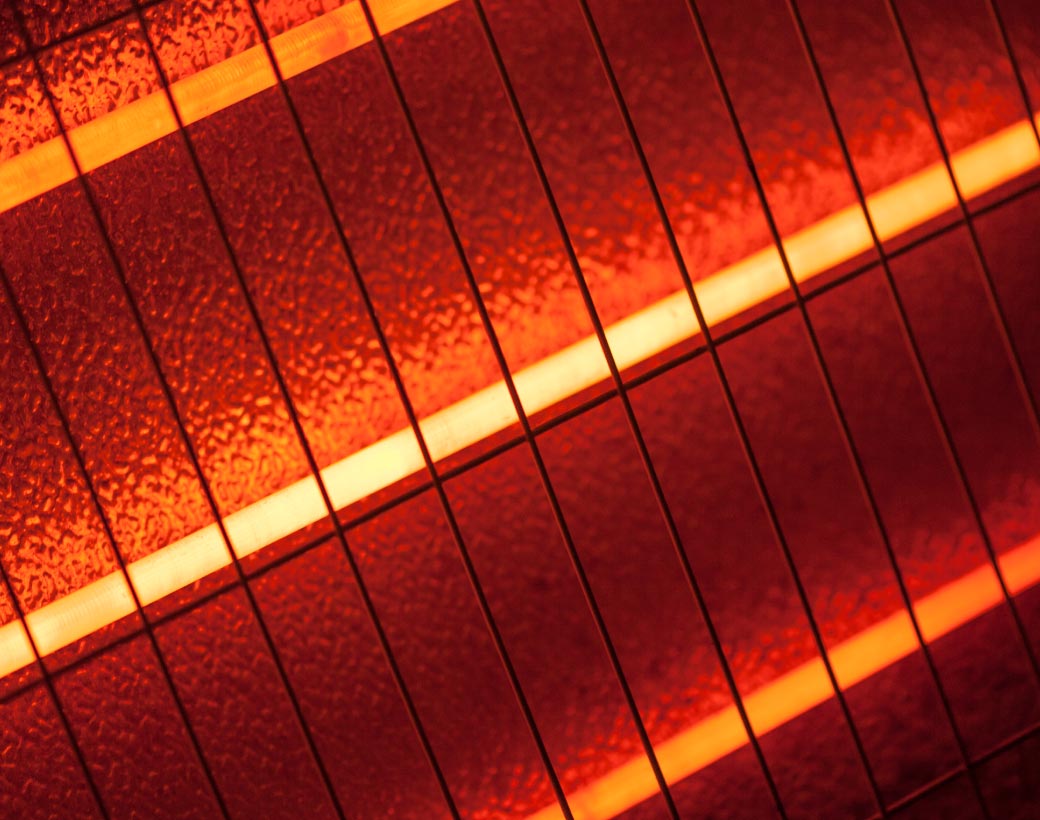

Increase comfort in your production area with radiant heating. Radiant heating warms the actual surfaces of your building and is more efficient than conventional heating systems. Radiant heat systems use high-heat infrared lamps which transfer heat energy via electromagnetic radiation to lower temperature surrounding materials. It’s used in large space buildings, usually installed above employee locations to make the area feel warmer than the remainder of the space. Radiant heat is actually safer and more efficient than conventional heating systems. Save on your energy costs and keep your employees comfortable and safe with a radiant heating system.

Humidification is important for regulating climate control for organic materials, especially in grow facilities and labs. Maintaining humidity levels for grower operations, for example, increases production output by providing plants with a comfortable environment in which to prosper. Dry climates can do a number on not only organics but also on furnishings (wood in particular) and equipment. Excessively dry work environments can also have effects on your employees; dry skin and sinus problems. Central humidification will enable you to properly regulate indoor humidity by automatically monitoring moisture levels in your building and constantly adjusting the amount of water vapor released into the air, keeping the humidity level constant and comfortable.

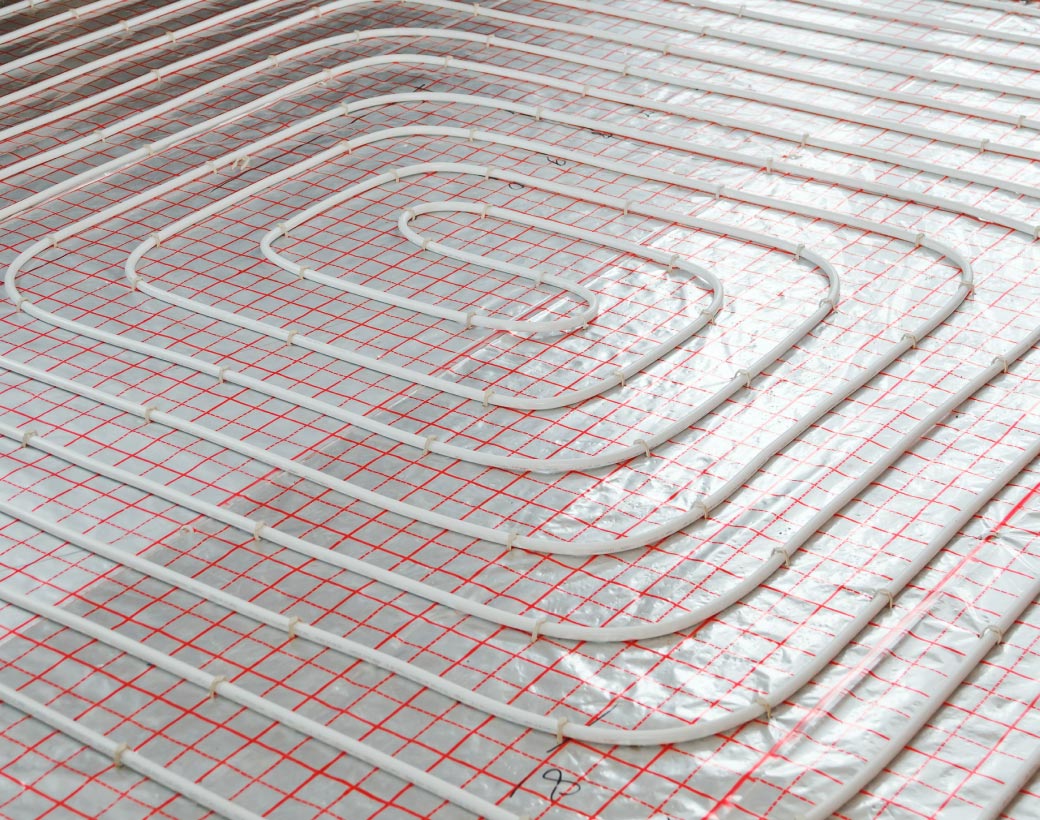

Radiant heating uses hot water tubing to circulate heat throughout your building in slab. Radiant heating is energy efficient, with energy usage shown to be around 70% lower than electric or furnace heating. The main reason being that water is a better conductor than air. If your facility is already using a boiler system for heating, radiant would be an ideal upgrade, as much of the needed equipment is already in place.

Having a problem that can’t wait? Our 24-hour emergency hotline is always open to your call, whether you are a new or existing customer. You can call us directly at (508) 644-2221 or hit the Emergency Services button at the top of the page, and we guarantee a response within 1 hour.

125 PSI air test, 125lb Hydro test completed on most installs. This may be adjusted depending on your specific equipment or specifications.