Published May 27, 2017

North Atlantic Corp. (NAC) is a distributor and manufacturer of windows, doors, kitchens, stairs, millwork and commercial openings. Their manufacturing facility is located in Somerset, Massachusetts. PSI has had the pleasure of serving NAC as a client since October 2004.

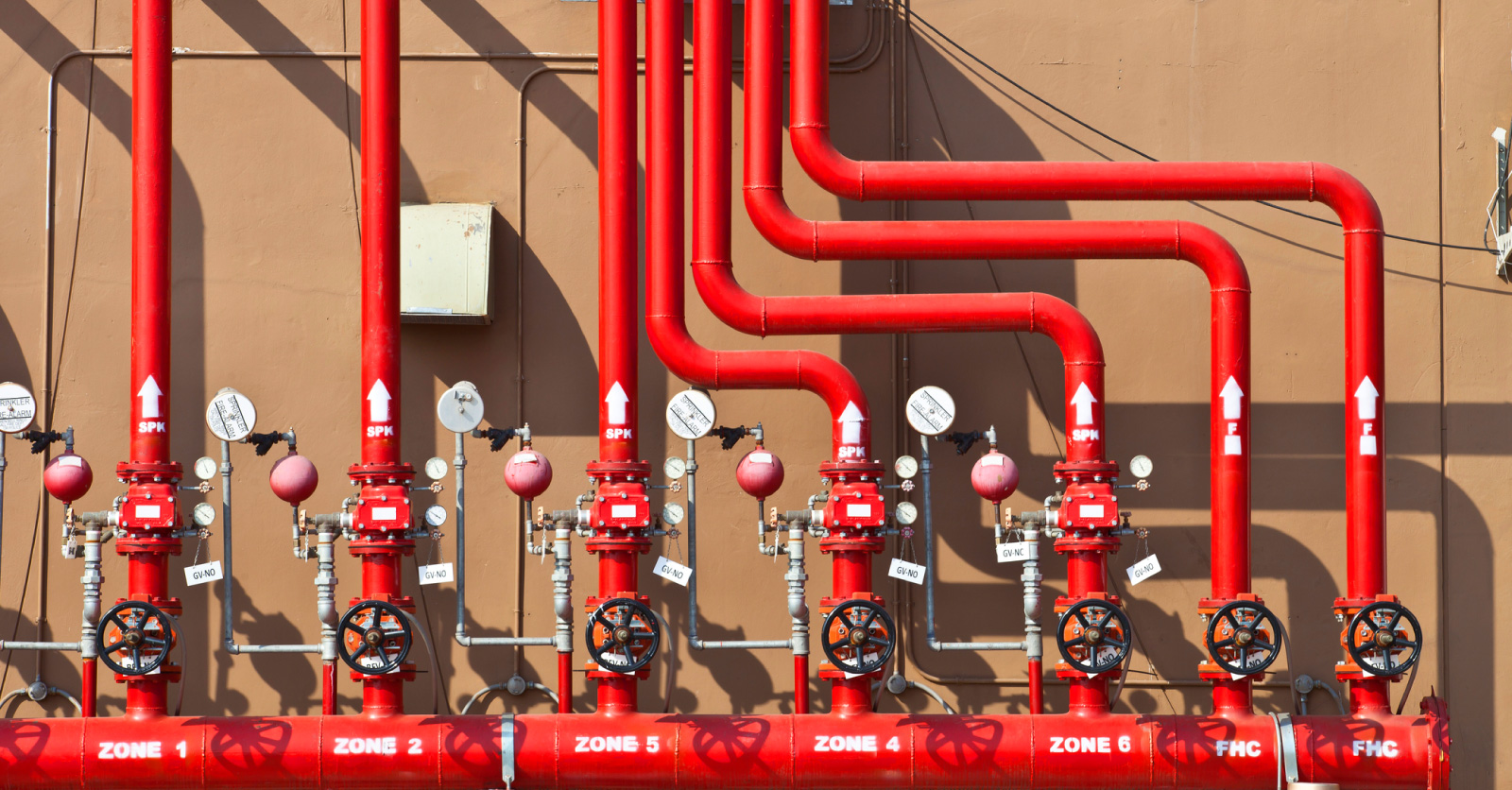

We were contracted to design and install an extra hazard fire protection system for a new addition onto the main building to be used manufacturing and storage. The addition consists of two levels, each measuring 20,000 square feet.

National Fire Protection Association (NFPA) promulgates guidelines for specific hazards depending on the combustibility of goods being stored in the area. Because the upper floor usage was considered higher than normal hazard, substantial water flow and pressure were required to meet the requirements. When higher pressure and water supply is necessary, sometimes a fire pump is warranted. Since fire pumps are sophisticated pieces of equipment that can be expensive and require additional maintenance, the goal is to eliminate the need for this equipment. Further complicating matters, the existing systems are presently protected by a “dry” system and the owner wished to maintain that strategy for the new area.

National Fire Protection Association (NFPA) promulgates guidelines for specific hazards depending on the combustibility of goods being stored in the area. Because the upper floor usage was considered higher than normal hazard, substantial water flow and pressure were required to meet the requirements. When higher pressure and water supply is necessary, sometimes a fire pump is warranted. Since fire pumps are sophisticated pieces of equipment that can be expensive and require additional maintenance, the goal is to eliminate the need for this equipment. Further complicating matters, the existing systems are presently protected by a “dry” system and the owner wished to maintain that strategy for the new area.

Since fire pumps are sophisticated pieces of equipment that can be expensive and require additional maintenance, the goal is to eliminate the need for this equipment.

One was to install a new fire pump serving the both the new and existing systems. The problem with that option was that the facility has been expanded several times in the past and presently has several incoming water maIns. To install a fire pump to serve only the new addition would be costly as well as impractical. Normally, a fire pump is designed to serve the entire facility, and in this case, it would be extremely difficult as there is no common point of connection to the incoming water supplies. After study, this idea was dropped.

Once we obtained the water flow test data, we calculated scenarios for several types of systems. It was apparent that a dry system would not meet code requirements without installing a fire pump. We discussed this with our client and it was agreed to install a wet system using the available city water supply with oversized piping to reduce the frictional losses.

Once we obtained the water flow test data, we calculated scenarios for several types of systems.

Since the addition was two stories, it was essential that the lower level be engineered to support the upper level storage weight. This meant that the steel support joists had to be placed close together; closer than typical construction calls for. Our client did not want the sprinkler piping to be below the supports because they wanted to keep as much head room as possible. Standard lengths of pipe usually come in 20 foot lengths. In order to be able to fit the pipe between the joists, it was our intention to cut the pipes into 10’ lengths allowing us to be able to slip them into the webbing space between the joists. However, on inspection of the situation, our project manager, Greg Brewer, VP of Fire Protection, recognized a potential problem. There were major support beams supporting the joists. That meant that each piece of piping would have to elbow down and then up leaving that fitting and section of pipe below the steel.

What if we could cut 2-inch holes into the exterior foundation wall and support beams allowing the pipes to be slipped into the joist spacing and thereby eliminate approximately 150 couplings and 64 elbows? This idea would not only keep the project on schedule by saving installation time, it would also eliminate 150 points of potential future leaks.

What if we could cut 2-inch holes into the exterior foundation wall and support beams allowing the pipes to be slipped into the joist spacing and thereby eliminate approximately 150 couplings and 64 elbows? This idea would not only keep the project on schedule by saving installation time, it would also eliminate 150 points of potential future leaks.

Although cutting holes in a foundation is not the optimum situation, NAC realized that it was the best alternative. Permission was granted by the structural engineer and NAC. The holes were marked and core drilled. A good sealing agent was used around the holes. There were no identifiable marks on the foundation.

Due to the project time schedule and delays in construction that were caused by factors beyond our control, we were asked to work several nights so our customer could receive the building occupancy in a timely fashion. Naturally we agreed and NAC received their occupancy on time.

At PSI we work together to create memorable relationships with our clients. Our “No Headache” policy means you can always count on us to be reliable, high-performing, professional, knowledgeable and highly-efficient problem solvers.

When you hire the PSI Team, you not only get process piping, fire protection, HVAC and electrical services, you also benefit by our award-winning safety program, our commitment to community and a warranty that goes well beyond the industry standard.

Be efficient with your time, and trust PSI to be efficient with your piping project. I promise in the long run, you will be thrilled. Have any questions? Drop us an email, psi@PipingSystemsIns.com or give us a call today at 508.644.2221.

A Fire Emergency Isn’t the Time to Put Your Sprinkler System to the Test

DOWNLOAD THE GUIDE NOW